青海地区产共轭亚油酸乳酸菌分离及其对青贮全株玉米品质的影响

English

-

表 1 ANCLA2处理对全株玉米青贮感官品质影响

Table 1 Effect of ANCLA2 on organoleptic properties of whole corn silage

处理 Treatment 项目得分 Score of item 总分

Score等级

Grade色泽 Color 气味 Odor 水分 Water 质地 Texture pH 对照组 Control 14 17 19 7 14 71 良好 Good 植物乳杆菌 LP-1

Lactobacillus plantarum LP-117 21 19 8 18 83 优质 Excellent 植物乳杆菌 LP-2

Lactobacillus plantarum LP-218 21 19 9 20 87 优质 Excellent 共轭亚油酸菌 ANCLA2-1

Lactobacillus producing conjugated linoleie acid ANCLA2-116 20 19 8 18 81 优质 Excellent 共轭亚油酸菌 ANCLA2-2

Lactobacillus producing conjugated linoleie acid ANCLA2-218 22 19 8 20 87 优质 Excellent 表 2 ANCLA2处理对全株玉米青贮发酵品质影响

Table 2 Fermentation sensory quality of whole corn silage

处理 Treatment 乳酸 LA/% 乙酸 AA/% 丙酸 PA/% 丁酸 BA/% 氨态氮占总氮比

NH3-N to total N ratio/%对照组 Control 5.26 ± 0.47c 1.68 ± 0.14b 0.28 ± 0.02a 0.09 4.01 ± 0.27a 植物乳杆菌 LP-1

Lactobacillus plantarum LP-16.47 ± 0.41b 1.75 ± 0.10b 0.25 ± 0.02b 0.00 3.62 ± 0.21b 植物乳杆菌 LP-2

Lactobacillus plantarum LP-27.03 ± 0.28a 1.72 ± 0.11b 0.22 ± 0.01c 0.00 3.35 ± 0.21c 共轭亚油酸菌 ANCLA2-1

Lactobacillus producing conjugated linoleie acid ANCLA2-16.51 ± 0.32b 1.83 ± 0.14a 0.27 ± 0.02a 0.00 3.68 ± 0.22b 共轭亚油酸菌 ANCLA2-2

Lactobacillus producing conjugated linoleie acid ANCLA2-27.22 ± 0.39a 1.69 ± 0.11b 0.23 ± 0.01c 0.00 3.41 ± 0.20c 文中未特别标注的物质含量均以干物质为基础,同列不同小写字母表示不同处理间差异显著(P < 0.05)。下同。

Substance content are based on dry matter if there is not particularly marked in text. Different lowercase letters within the same column indicate significant difference among different treatments at the 0.05 level; LA, lactic acid; AA, acetic acid; PA, propionic acid; BA, butyric acid; similarly for the following tables.表 3 产CLA乳杆菌菌剂处理对全株玉米青贮营养成分影响

Table 3 Fermentation quality of whole corn silage

组别

Treatment干物质

DM/%粗蛋白

CP/%中性洗涤纤维

NDF/%酸性洗涤纤维

ADF/%粗脂肪

EE/%共轭亚油酸

CLA/(µg·g–1)对照组 Control 25.94 ± 1.36a 8.91 ± 0.55a 44.73 ± 1.24c 25.82 ± 0.61b 3.78 ± 0.05d 1.53 ± 0.18d 植物乳杆菌 LP-1

Lactobacillus plantarum LP-124.22 ± 1.28b 8.74 ± 0.53a 45.98 ± 1.31b 27.17 ± 1.59a 3.85 ± 0.06c 2.32 ± 0.41c 植物乳杆菌 LP-2

Lactobacillus plantarum LP-223.75 ± 1.87bc 7.86 ± 0.62b 45.32 ± 1.98b 27.89 ± 1.55a 3.89 ± 0.08c 2.56 ± 0.45c 共轭亚油酸菌 ANCLA2-1

Lactobacillus producing conjugated linoleie acid ANCLA2-125.11 ± 1.35b 8.63 ± 0.53a 47.44 ± 1.15a 26.81 ± 1.58a 4.10 ± 0.09b 9.73 ± 1.25b 共轭亚油酸菌 ANCLA2-2

Lactobacillus producing conjugated linoleie acid ANCLA2-222.97 ± 1.56c 8.12 ± 0.52b 45.96 ± 1.26b 27.56 ± 1.51a 4.23 ± 0.10a 13.62 ± 0.94a DM, dry matter; CP, crude protein; NDF, neutral detergent fiber; ADF, acid detergent fiber; EE, ether extract; CLA, conjugated linoleic acid. -

[1] KOBA K, YANAGITA T. Health benefits of conjugated linoleic acid (CLA). Obesity Research & Clinical Practice, 2014, 8(6): e525-e532.

[2] PINI M, TOUCH S, NIOT I, POIRIER H, CLÉMENT K, ANDRÉ S, GUERRE-MILLO M. Oral administration of trans10, cis12 conjugated linoleic acid (cla) in mice increases immune cell abundance in the adipose tissue but not in the intestine. Helicobacter, 2014, 19: 80.

[3] VILADOMIU M, HONTECILLAS R, BASSAGANYA-RIERA J. Modulation of inflammation and immunity by dietary conjugated linoleic acid. European Journal of Pharmacology, 2016, 785: 87-95. doi: 10.1016/j.ejphar.2015.03.095

[4] THORSTEN B, ROSWITHA M, IMME L, ALFONSO L. Absorption and metabolism of cis‐9, trans‐11‐CLA and of its oxidation product 9,11‐furan fatty acid by Caco‐2 cells. Lipids, 2012, 47(4): 435-442. doi: 10.1007/s11745-012-3653-6

[5] FERNANDEZ-AVILA C, ARRANZ E, GURI A, TRUJILLO A J, CORREDIG M. Vegetable protein isolate-stabilized emulsions for enhanced delivery of conjugated linoleic acid in Caco-2 cells. Food Hydrocolloids, 2016, 55: 144-154. doi: 10.1016/j.foodhyd.2015.10.015

[6] GARCIA C, DUBY C, CATHELINE D, TORAL G, BERNARD L, LEGRAND P, RIOUX V. Synthesis of the suspected trans-11, cis-13 conjugated linoleic acid isomer in ruminant mammary tissue by FADS3-catalyzed Δ13-desaturation of vaccenic acid. Journal of Dairy Science, 2017, 100(1): 783-796. doi: 10.3168/jds.2016-11455

[7] BERDEAUX O, CHRISTIE W W, GUNSTONE F D, SEBEDIO J L. Large-scale synthesis of methyl cis-9, trans-11-octadecadienoate from methyl ricinoleate. Journal of the American Oil Chemists' Society, 1997, 74(8): 1011-1015. doi: 10.1007/s11746-997-0018-z

[8] DEVI B L, MUTHIAH N S, MURTY K S N, KUMAR S. Effects of 12 weeks treatment with conjugated linoleic acid supplementation on body fat mass and lipid metabolism in healthy, obese individuals-A pilot study. Research Journal of Pharmacy and Technology, 2018, 11(3): 996-1000. doi: 10.5958/0974-360X.2018.00186.5

[9] BENBROOK C M, DAVIS D R, HEINS B J, LATIF M A, LEIFERT C, PETERMAN L, BUTLER G, FAERGEMAN O, ABEL‐CAINES S, BARANSKI M. Enhancing the fatty acid profile of milk through forage‐based rations, with nutrition modeling of diet outcomes. Food Science & Nutrition, 2018, 6(3): 681-700. doi: 10.1002/fsn3.610

[10] SIURANA A, CALSAMIGLIA S. A meta analysis of feeding strategies to increase the content of conjugated linoleic acid (CLA) in dairy cattle milk and the impact on daily human consumption. Animal Feed Science and Technology, 2016, 217: 13-26. doi: 10.1016/j.anifeedsci.2016.04.013

[11] KELSEY J A, CORL B A, COLLIER R J, BAUMAN D E. The effect of breed, parity, and stage of lactation on conjugated linoleic acid (CLA) in milk fat from dairy cows. Journal of Dairy Science, 2003, 86(8): 2588-2597. doi: 10.3168/jds.S0022-0302(03)73854-5

[12] CONTE G, SERRA A, CREMONESI P, CHESSA S, CASTIGLIONI B, CAPPUCCI A, BULLERI E, MELE M. Investigating mutual relationship among milk fatty acids by multivariate factor analysis in dairy cows. Livestock Science, 2016, 188: 124-132. doi: 10.1016/j.livsci.2016.04.018

[13] PASZCZYK B, BRANDT W, LUCZYNSKA J. Content of conjugated linoleic acid (cla) and trans isomers of c18: 1 and c18: 2 acids in fresh and stored fermented milks produced with selected starter cultures. Czech Journal of Food Science, 2016, 34(5): 391-396. doi: 10.17221/CJFS

[14] DOREAU M, MEYNADIER A, FIEVEZ V, FERLAY A. Ruminal metabolism of fatty acids: Modulation of polyunsaturated, conjugated, and trans fatty acids in meat and milk// WATSON R R, DE MEESTER F. Handbook of Lipids in Human Function: Fatty Acids. San Diego, USA and Oxfor, UK: Academic Press and AOCS Press, 2016.

[15] EGGERT J M, BELURY M A, KEMPA S A, MILLS S E, SCHINCKEL A P. Effects of conjugated linoleic acid on the belly firmness and fatty acid composition of genetically lean pigs. Animal Science, 2001, 79: 2866-2872. doi: 10.2527/2001.79112866x

[16] ISMAIL M M, TABEKHA M M, EL-BORAEY N A, ZIDAN M S. Chemical composition, microbial properties and sensory evaluation of yoghurt made from buffalo, cow and soy milk mixtures. International Journal of Scientific Research in Science and Technology, 2016, 2(5): 246-260.

[17] GORISSEN L, LEROY F, DE VUYST L, BOERS A, VANHEULE S. Bacterial production of conjugated linoleic and linolenic acid in foods:A technological challenge. Critical Reviews in Food Science and Nutrition, 2015, 55(11): 1561-1574. doi: 10.1080/10408398.2012.706243

[18] RIBEIRO S C, STANTON C, YANG B, ROSS R P, SILVAA C C G. Conjugated linoleic acid production and probiotic assessment of Lactobacillus plantarum isolated from Pico cheese. LWT - Food Science and Technology, 2017, 90: 403-411.

[19] 王林, 孙启忠, 张慧杰. 苜蓿与玉米混贮质量研究. 草业学报, 2011, 20(4): 202-209. WANG L, SUN Q Z, ZHANG H J. A study on quality of mixed silage of alfalfa and corn. Acta Prataculturae Sinica, 2011, 20(4): 202-209.

[20] 闫峻, 高玉鹏, 王文杰, 穆淑琴. 全株玉米青贮饲料在贮存期营养品质的变化规律. 西北农林科技大学学报, 2009, 37(8): 75-80. YAN J, GAO Y P, WANG W J, MU S Q. Variation law of whole-plant corn silage nutritional quality under different storage periods. Journal of Northwest A & F University, 2009, 37(8): 75-80.

[21] HONKANEN A M, LESKINEN H, TOIVONEN V, MCKAINET N. Metabolism of α-linolenic acid during incubations with strained bovine Rumen contents:Products and mechanisms. British Journal of Nutrition, 2016, 115(12): 2093-2105. doi: 10.1017/S0007114516001446

[22] MCKAIN N, SHINGFIELD K J, WALLACE R J. Metabolism of conjugated linoleic acids and 18: 1 fatty acids by ruminal bacteria:Products and mechanisms. Microbiology, 2010, 156(2): 579-588. doi: 10.1099/mic.0.036442-0

[23] RENES E, LINARES D M, GONZÁLEZ L, FRESNO J M, TORNADIJO M E, STANTON C. Production of conjugated linoleic acid and gamma-aminobutyric acid by autochthonous lactic acid bacteria and detection of the genes involved. Journal of Functional Foods, 2017, 34: 340-346. doi: 10.1016/j.jff.2017.05.014

[24] 方丽, 闵伟红, 刘嘉, 刘景圣. 产共轭亚油酸鼠李糖乳杆菌的筛选与鉴定. 中国食物与营养, 2012, 18(5): 33-36. doi: 10.3969/j.issn.1006-9577.2012.05.008 FANG L, MIN W H, LIU J, LIU J S. Conjugated linoleic acid Lactobacillus rhamnosus screening identification. Food and Nutrition in China, 2012, 18(5): 33-36. doi: 10.3969/j.issn.1006-9577.2012.05.008

[25] 刘春晓. 内蒙传统发酵奶油制品中CLA产生菌的筛选及发酵条件优化. 呼和浩特: 内蒙古农业大学硕士学位论文, 2016. LIU C X. Screening of bacteria with CLA producing ability from traditional fermentation cream products of Inner Mongolia and optimization of the fermentation conditions. Master Thesis. Hohhot:Inner Mongolia Agricultural University, 2016.

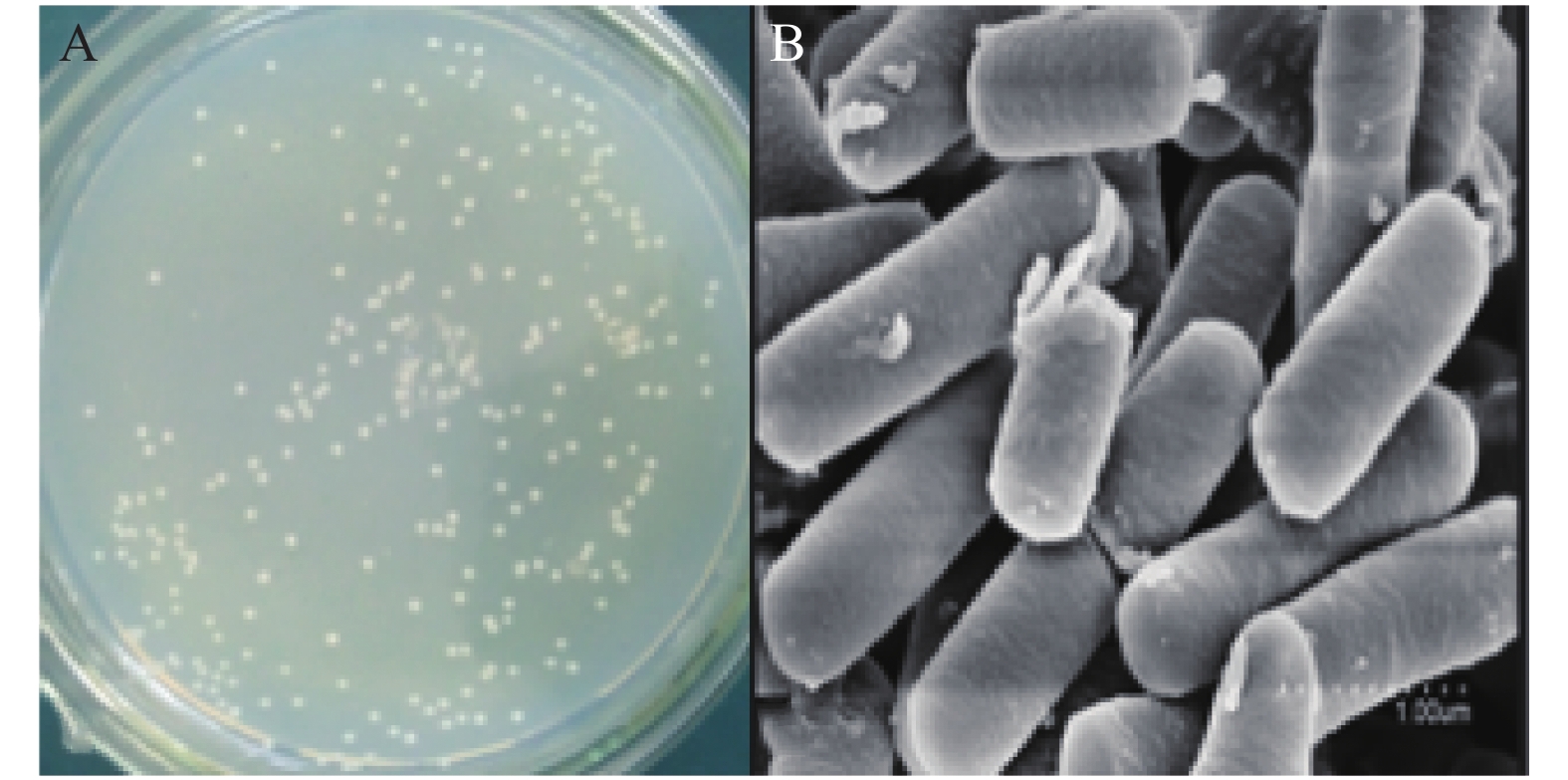

[26] 杜波, 陈丽娟, 王力生, 王菊花, 蔡玉华, 高翔, 方华平, 刘莉君, 马广智, 程茂基. 玉米青贮中产共轭亚油酸菌的筛选与鉴定. 食品与生物技术学报, 2008, 27(1): 90-94. doi: 10.3321/j.issn:1673-1689.2008.01.017 DU B, CHEN L J, WANG L S, WANG J H, CAI Y H, GAO X, FANG H P, LIU L J, MA G Z, CHENG M J. Screening and identification of lactic acid bacteria for biosynthesis of conjugated linoleic acid from maize silage. Journal of Food Science and Biotechnology, 2008, 27(1): 90-94. doi: 10.3321/j.issn:1673-1689.2008.01.017

[27] DAHIYA D K, PUNIYA A K. Isolation, molecular characterization and screening of indigenous lactobacilli for their abilities to produce bioactive conjugated linoleic acid (CLA). Journal of Food Science and Technology, 2017, 54(3): 792-801. doi: 10.1007/s13197-017-2523-x

[28] MULROONEY C N, KUNG L Jr. Short communication: The effect of water temperature on the viability of silage inoculants. Journal of Dairy Science, 2008, 91(1): 236-240. doi: 10.3168/jds.2007-0449

[29] 张亚格, 字学娟, 李茂, 周汉林. 有机酸对柱花草青贮品质和营养成分的影响. 动物营养学报, 2016, 28(5): 1609-1614. doi: 10.3969/j.issn.1006-267X.2016.05.039 ZHANG Y, ZI X J, LI M, ZHOU H L. Effects of organic acids on quality and nutrient composition of Stylosanthes guianensis silage. Chinese Journal of Animal Nutrition, 2016, 28(5): 1609-1614. doi: 10.3969/j.issn.1006-267X.2016.05.039

[30] 张淑枝, 周振明, 孟庆翔. 不同生物添加剂对于全株玉米青贮发酵品质及消化率的影响. 中国畜牧杂志, 2007, 43(1): 53-55. doi: 10.3969/j.issn.0258-7033.2007.01.018 ZHANG S Z, ZHOU Z M, MENG Q X. Effects of different biology additives on the fermentation quality and digestibility of whole corn silage in vitro. Chinese Journal of Animal Science, 2007, 43(1): 53-55. doi: 10.3969/j.issn.0258-7033.2007.01.018

[31] SHAO T, SHIMOJO M, WANG T, MASUDA Y. Effect of additives on the fermentation quality and residual mono and disaccharides compositions of forage oats (Avena sativa L.) and Italianry egrass (Lolium multiflorum Lam.) silages. Asian Australasian Journal of Animal Sciences, 2005, 18(11): 1582-1588. doi: 10.5713/ajas.2005.1582

[32] WEATHERBURN M W. Phenol hypochlorite reaction for determination of ammonia. Analytical Chemistry, 1967, 39(8): 971-974. doi: 10.1021/ac60252a045

[33] 薛秀恒, 王菊花, 王志耕. 饲料调控对奶牛共轭亚油酸合成的影响. 饲料博览, 2004(3): 28-31. doi: 10.3969/j.issn.1001-0084.2004.03.017 XUE X H, WANG J H, WANG Z G. Influence of feed regulation and control on diary conjugate linoleic acid synthetase. Feed Review, 2004(3): 28-31. doi: 10.3969/j.issn.1001-0084.2004.03.017

[34] HOLT J G, KRIEG R N, SNEATH P H A, STALEY J T, WILLIAMS S T. Bergey’s Manual of Determinative Bacteriology. 9th ed. Baltimore: Williams and Wilkins,1994.

[35] HERRMANN C, HEIERMANN M, IDLER C. Effects of ensiling, silage additives and storage period on methane formation of biogas crops. Bioresource Technology, 2011, 102(8): 5153-5161. doi: 10.1016/j.biortech.2011.01.012

[36] SAMBUSITI C, MONLAU F, FICARA E, CARRÈREB H, MALPEIA F. A comparison of different pre-treatments to increase methane production from two agricultural substrates. Applied Energy, 2013, 104: 62-70. doi: 10.1016/j.apenergy.2012.10.060

[37] 储徐建, 李长慧, 刘明灿, 李彩娟, 赵明霞. 耐低温乳酸菌的分离与优化培养. 草业科学, 2014, 31(7): 1380-1388. CHU X J, LI C H, LIU M C, LI C J, ZHAO M X. Isolation and optimization of low temperature lactic acid bacteria. Pratacultural Science, 2014, 31(7): 1380-1388.

[38] CAVINATO C, DA ROS C, PAVAN P, BOLZONELLAB D. Influence of temperature and hydraulic retention on the production of volatile fatty acids during anaerobic fermentation of cow manure and maize silage. Bioresource Technology, 2017, 223: 59-64. doi: 10.1016/j.biortech.2016.10.041

[39] SRIGOPALRAM S, PARK H S, ILAVENIL S, DA H K, ARASU M V, KUPPUSAMY P, KYUNG D L, KI C C. Isolation, in vitro probiotic characterization of Lactobacillus plantarum and its role on Italian ryegrass silage quality enhancement. International Journal of Agriculture & Biology, 2017, 19(1): 164-170.

[40] XU Z, HE H, ZHANG S, KONG J. Effects of inoculants Lactobacillus brevis and Lactobacillus parafarraginis on the fermentation characteristics and microbial communities of corn stover silage. Scientific Reports, 2017, 7(1): 13614. doi: 10.1038/s41598-017-14052-1

[41] 贾婷婷, 吴哲, 玉柱. 不同类型乳酸菌添加剂对燕麦青贮品质和有氧稳定性的影响. 草业科学, 2018, 35(5): 1266-1272. JIA T T, WU Z, YU Z. Effect of different lactic acid bacteria additives on the fermentation quality and aerobic stability of oat silage. Pratacultural Science, 2018, 35(5): 1266-1272.

[42] 侯建建, 白春生, 张庆, 玉柱. 单一和复合乳酸菌添加水平对苜蓿青贮营养品质及蛋白组分的影响. 草业科学, 2016, 33(10): 2119-2125. HOU J J, BAI C S, ZHANG Q, YU Z. Effects of different additive amount of single and multiple lactic acid bacteria on the silage quality and protein fractions of alfalfa. Pratacultural Science, 2016, 33(10): 2119-2125.

[43] SUCU E, KALKAN H, CANBOLAT O, FILYA I. Effects of ensiling density on nutritive value of maize and sorghum silages. Revista Brasileira de Zootecnia, 2016, 45(10): 596-603. doi: 10.1590/S1806-92902016001000003

[44] HOFFMAN P C, FUNK D A. Applied dynamics of dairy replacement growth and management. Journal of Dairy Science, 1992, 75: 2504. doi: 10.3168/jds.S0022-0302(92)78012-6

[45] 侯美玲, 格根图, 孙林, 周天荣, 张颖超, 贾玉山. 甲酸,纤维素酶,乳酸菌剂对典型草原天然牧草青贮品质的影响. 动物营养学报, 2015, 27(9): 2977-2986. doi: 10.3969/j.issn.1006-267x.2015.09.039 HOU M, GE G T, SUN L, ZHOU T R, ZHANG Y C, JIA Y S. The effects of formic acid, cellulose and lactic acid bacteria on silage quality of natural forage of typical steppe. Chinese Journal of Animal Nutrition, 2015, 27(9): 2977-2986. doi: 10.3969/j.issn.1006-267x.2015.09.039

[46] 王启芝, 黄光云, 黄丽霞, 黄香, 周俊华, 周志扬. 米曲霉对玉米秸秆青贮营养价值的影响. 黑龙江畜牧兽医, 2017(6): 179-180. WANG Q Z, HUANG G Y, HUANG L X, HUANG X, ZHOU J H, ZHOU Z Y. Effects of Aspergillus niger on the nutritional value of corn stalk silage. Heilongjiang Animal Husbandry Veterinarian, 2017(6): 179-180.

-

期刊类型引用(3)

1. 刘杨,冯曌卓,王茄灵,秦维,安巍,王亚军,闫志英. 枸杞种植废弃物固态发酵生物饲料条件优化及其微生物群落. 应用与环境生物学报. 2023(06): 1434-1443 .  百度学术

百度学术

2. 郭小婧,张东辉. 乳酸菌合成共轭亚油酸及其应用研究进展. 食品研究与开发. 2020(09): 182-189 .  百度学术

百度学术

3. 倪印锋,王明利. 中国青贮玉米产业发展时空演变及动因. 草业科学. 2019(07): 1915-1924 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: